📏 Shared International Standards — The Global Baseline

Why are airport fire trucks different from municipal fire engines

- Airport fire trucks — also known as Aircraft Rescue and Fire Fighting (ARFF) vehicles or crash tenders — are purpose-built not for structure fires in buildings, but for aircraft emergencies: fuel fires, runway accidents, evacuation, and rescue in potentially dangerous aviation settings.

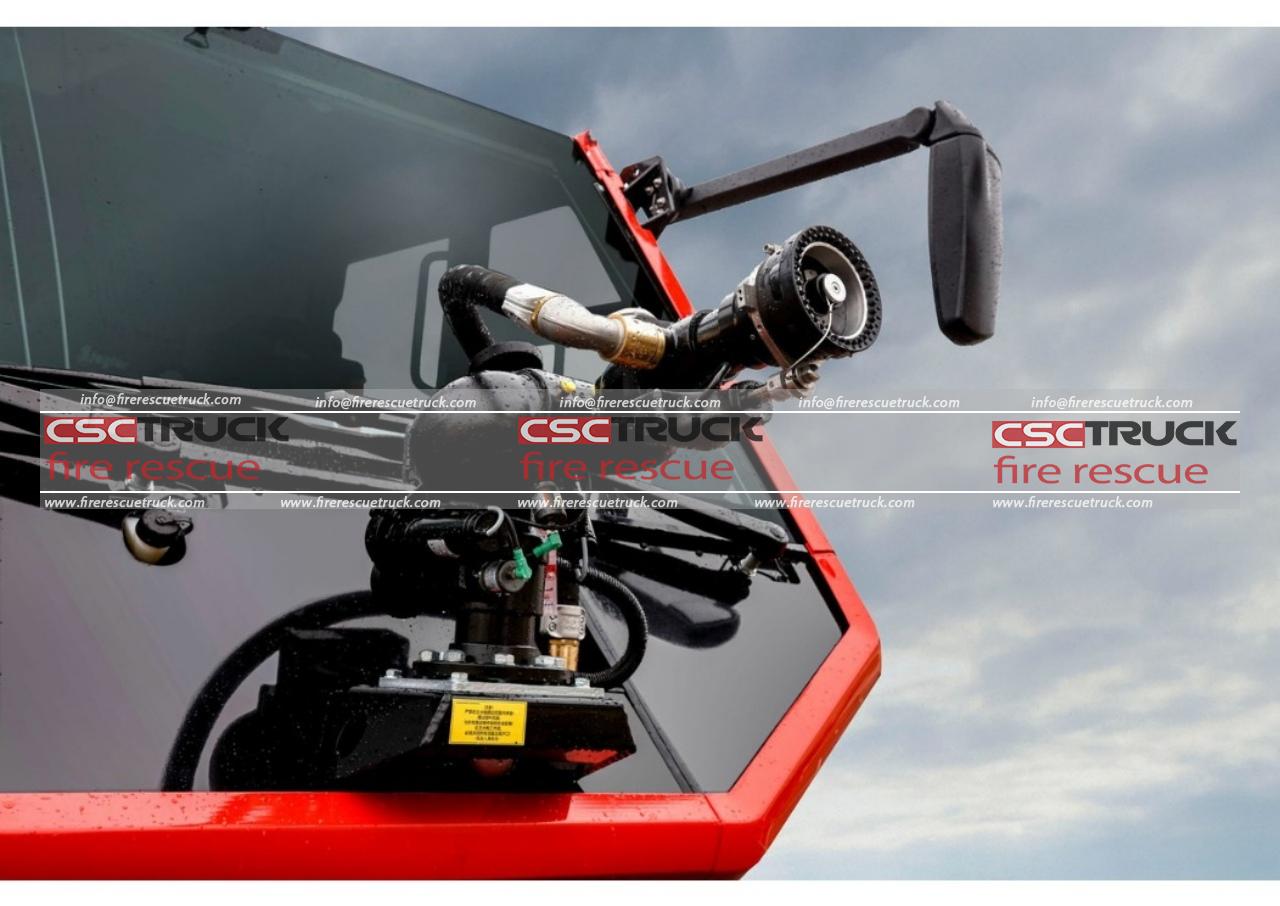

- That means they need to combine capabilities: high‑speed response (even across runways or rough terrain), large onboard reserves of water/foam and sometimes dry chemical agents, and powerful pumps/nozzles (including roof‑mounted cannons, under‑truck nozzles, or booms capable of reaching high or difficult angles).

- Also, because aircraft fires often involve jet fuel (high heat, spreading fire, possibly hazardous materials), ARFF crews need special training — in aviation‑specific rescue, use of foam/dry‑chemical agents, hazardous‑materials awareness, and emergency evacuation — rather than typical urban firefighting.

Regulatory framework — the role of the International Civil Aviation Organization (ICAO)

- The primary global standard is set by ICAO Annex 14, Volume 1, which defines minimum requirements for aerodrome Rescue and Fire Fighting Services (RFFS), including the number and type of vehicles, amount of extinguishing agents, response times, and training requirements — depending on the size of aircraft served.

- Under Annex 14, airports are assigned a category (e.g., 1–10) based on the largest aircraft normally using them; that category determines minimum ARFF provisions: how many and what kind of firefighting vehicles, how much foam/water, how many trained personnel, etc.

- Each country or region then transposes ICAO’s requirements into local regulation (e.g., in Europe through the regulatory regime under the European Union Aviation Safety Agency (EASA) for EU airports, or equivalent national civil aviation authorities) to implement RFFS planning and oversight.

➡️ The implication: regardless of whether an airport is in Europe, Asia, Africa, or elsewhere, the fundamental mission and baseline design requirements for ARFF vehicles — speed, extinguishing capacity, pump/discharge performance, rapid response, specialized crew training — are broadly shared globally.

🚒 Commonly Used European‑Origin Fire Trucks in Both Europe and Asia — But a European Design Ethos

Even in Asia, a large share of ARFF vehicles are manufactured by traditionally European firms. A representative example is the widely used Rosenbauer Panther, originally developed in Europe.

What defines the Rosenbauer Panther (and by extension, many “European-style” ARFFs)

- The Panther is offered in 4×4, 6×6, and 8×8 wheel configurations, reflecting flexibility depending on the airport’s size and threat assessment.

- Larger variants (like 6×6 or 8×8) offer large extinguishing agent volumes — e.g., the 6×6 can carry up to ~14,000 liters, with high-capacity pumps and turrets for foam/water discharge, capable of 9,000 l/min or more.

- They feature advanced cabin design for crew safety and ergonomics: crash-tested cabins (in line with European vehicle safety standards, e.g., chassis/cab structural integrity certification), panoramic visibility for driver and crew, and often modern control systems integrating camera-based surround‑view (“Birdview”) and electronic stability control.

- Performance is high: even heavy units can accelerate quickly (for their size) and reach sufficient top speeds. For example, Panther’s performance package — with powerful diesel engines and automatic transmissions — allows rapid sprint to a crash site, enabling the “first‑on‑scene” within the typical 3–4 minute window required for runway emergencies.

Adoption in Asia — showing global standardization but with local operational contexts

- Many large airports in Asia — especially in countries upgrading civil aviation infrastructure — import European-designed ARFF vehicles. For example, some airport fire services in Asia operate Rosenbauer 8×8 ARFF tenders.

- The use of European-origin ARFF trucks in Asia suggests that the baseline global standards (per ICAO) plus the proven reliability and performance of European designs make them attractive regardless of region.

Thus, what we might call “European-style” ARFF design — robust, high‑powered, safety- and ergonomics-conscious, heavy-duty — is not confined to Europe alone; it often serves as the backbone for many modern Asian airport firefighting fleets too.

🌏 Regional Variations: How “Asian Airport Fire Trucks” May Diverge in Use, Deployment & Context

While many Asian airports use European-made ARFF vehicles, there are nonetheless regional variations — not always because of design differences, but because of operational context, budget constraints, airport size, local environment, and regulatory adaptation. Here are several of those variations:

1. Mix of imported and locally adapted vehicles

- In many Asian countries, ARFF fleets may include a mix: Imported heavy crash tenders (e.g., from European manufacturers) for major international airports, and lighter or simpler “crash fire tenders” (CFTs) for smaller or regional airports. For example, technical specifications from a smaller airport define CFT requirements on a 6×6 imported chassis (or equivalent), with at least a 480 HP diesel engine, full pump capability, foam/water tank, automatic transmission — but likely less capacity than large European‑standard units.

- This reflects that not all airports in Asia serve large wide‑body jets; some serve smaller regional aircraft, so their ARFF requirements (based on the airport’s category) may be lower. In such cases, a lighter, less costly ARFF/CFT suffices to meet regulatory requirements.

2. Diverse terrain or climate — sometimes a challenge

- Some airports in Asia are located in regions with extreme climates (heat, humidity, monsoon, tropical storms) or varied ground conditions (soft ground, sandy soil, rain‑soaked terrain). The ARFF vehicles there must handle not only paved runways but potentially off‑pavement terrain — meaning robust driveline and suspension, good traction, and reliability. Specified crash‑tender technical requirements (e.g., in some Asian airport procurement documents) call explicitly for 6×6 drive, heavy-duty suspension, automatic transmission, and the ability to traverse “rough, soft or sandy terrain” while still pumping foam or water as needed.

- That said, climate may also push local authorities to choose more modest capacity trucks (lower foam/water volumes) or incremental upgrades, balancing performance requirements with cost and maintenance constraints.

3. Regulatory and resource constraints can affect real-world compliance

- Although the global standard (ICAO) provides minimums, enforcement and consistent maintenance/training vary across different countries in Asia. In some cases, older ARFF vehicles persist well past their optimal life, or spare‑part shortages slow procurement of new units. For example, a previous review of government-operated airports mentioned some older ARFF units dating back decades, with parts unavailability leading to decommissioning.

- As a result, while the aspiration is to meet international standards, actual capacity or readiness may vary more widely than in major European airports with well-funded fire departments.

4. Use of non‑European (or hybrid) technology approaches

- Some airports in Asia (and globally) have begun experimenting with hybrid powertrains for ARFF vehicles, in part to address environmental concerns, operational costs, or regulatory pressure. For example, the manufacturer Scania announced a hybrid diesel‑electric solution for airport fire trucks: combining a combustion engine with an electric motor to deliver high horsepower when needed (for sprint to crash site) while enabling zero-emission or low-emission movement inside the airport for routine operations or patrols.

- Such adaptations show how regional operators — including in Asia — might adopt more sustainable technologies while still meeting the core performance requirements of ARFF.

🇪🇺 Why “European” Design Emphasis — and Its Operational Logic

It’s useful to reflect on what motivates the design ethos commonly associated with European ARFF trucks. Some of these design decisions resonate universally, others reflect regional priorities.

- Safety and crew protection: European standards — including chassis/cab safety certification (e.g., crash‑test compliance) and ergonomic operator compartments — emphasize protecting firefighters under high-stress, high-risk conditions. The cabin of a Panther, for instance, has been real‑world crash-tested and designed with panoramic visibility, seatbelt tensioners, optional airbags, stability control, and other modern safety gear.

- Performance and reliability: European ARFF vehicles are often built on purpose-built (not merely commercial) chassis; they have powerful engines (hundreds to over a thousand horsepower), high-capacity pumps, robust transmissions — enabling strong acceleration, high top speeds, and sustained pump operation — essential for the “first arrival and suppression” mission.

- Modularity and scalability: Because European airports vary widely — from small regional strips to major hubs — ARFF manufacturers design modular platforms (e.g., 4×4, 6×6, 8×8) so airports can choose according to their needs. This scalability of design means the same basic platform can be adapted to many different environments, including overseas.

- Regulatory alignment and standardization: European ARFF designs tend to reflect harmonized vehicle and safety standards (road/vehicle safety, manufacturing quality, crew protection, maintenance regimes) which — while not always identical globally — provide a strong baseline for reliability and interoperability, especially when airports worldwide buy from the same manufacturers.

Thus, “European” ARFF design is not just a regional aesthetic — it reflects a deliberate prioritization of performance, safety, standardization, and long-term reliability, which often appeals to airports globally, including in Asia.

⚠️ Operational Realities: Why “Asian Airport Fire Trucks” — in practice — Can Vary Widely

Because of the varying economic, infrastructural, and regulatory contexts across Asia, “airport fire truck fleets” in Asian countries can look very different from the idealized European model. Some factors:

- Airport size and traffic mix: Smaller regional airports handling turboprops or light jets may be assigned lower RFFS categories — requiring fewer or lighter ARFF vehicles (or just CRF tenders with limited capacity) — reducing the need (or budget) for heavy 8×8 crash tenders.

- Budget and resource constraints: Especially in developing or expanding aviation markets, cost constraints may drive the procurement of simpler vehicles, or delay upgrades; maintenance, spare parts, and periodic crew training may also lag behind ideal standards. This can lead to older vehicles staying in service longer, or sub-optimal readiness, especially in less-trafficked airports.

- Environmental and terrain considerations: Some airports may require vehicles optimized for sandy soil, monsoon‑soaked runways, high humidity, or high heat — meaning that selection of ARFF vehicles must take into account local terrain/climate, not just generic performance specs. Procurement documents sometimes specify chassis and suspension suited to soft or sandy ground and continuous pump operation regardless of load or movement.

- Adaptation to local fire codes and regulations: While many countries adopt ICAO standards, local civil aviation authorities may interpret or enforce them differently, resulting in variations in agent reserves, crew training frequency, maintenance cycles, or redundancy requirements — affecting how “European‑level” ARFF readiness is implemented.

- Diverse fleet composition: In Asia, it is common for a single airport’s firefighting fleet to include a mix: heavy imported crash tenders, lighter local tenders or rapid-intervention vehicles, and possibly converted or older trucks — reflecting pragmatic balancing of cost, maintenance, readiness, and operational demands. For example, in provincial or smaller airports, 6×6 CFT with ~480 HP engines might be preferred over 8×8 heavy crash tenders.

Hence, “Asian airport fire trucks” are rarely a monolith: there’s broad diversity, shaped by economic, geographic, regulatory, and operational factors.

🧯 The Middle Ground — Globalization Means More Convergence Than Divergence

While regional differences persist, the overall trend — especially in the past few decades — has been toward global convergence of ARFF standards and equipment. Some reasons:

- Many Asian airports, especially major international hubs or newly constructed airports, now procure European– or international‑spec ARFF vehicles (e.g., Rosenbauer crash tenders) rather than local, ad-hoc builds.

- The global regulatory influence of ICAO Annex 14 ensures a baseline of required capacity, response times, and crew training — meaning that even geographically distant airports follow similar rules for RFFS design.

- Innovations — like hybrid diesel‑electric ARFF vehicles, improved ergonomic cabs, advanced pumping and foam systems — are marketed globally, allowing Asian airports to adopt “state-of-the-art” design just like their European counterparts.

- As global air travel expands — including in Asia — the demand for standardized high-capacity firefighting systems increases. This encourages adoption of proven crash tenders rather than locally improvised solutions.

So although there is some regional variation, there is a strong shared foundation — meaning that in many respects, “European vs. Asian” is increasingly a matter of deployment context and resource availability, rather than fundamentally different design philosophies.

✅ Conclusion — What the Differences (and Similarities) Tell Us

- The core mission of ARFF / airport crash tenders — rapid response, fuel‑fire suppression, rescue — is universal. International standards (especially those set by ICAO) provide a common framework that airports worldwide strive to meet.

- “European-style” ARFF trucks — typified by robust design, high engine power, large extinguishing capacities, advanced crew protection, and modular chassis options — offer a proven, high-quality solution and are widely used around the world, including across many airports in Asia.

- In Asian contexts, however, practical considerations — airport size, traffic type, budget, terrain/climate, maintenance resources — influence the mix and type of fire trucks used: from heavy imported crash tenders for major airports, to lighter crash fire tenders or simpler vehicles for smaller or regional airports.

- The result is a diverse but increasingly standardized global ARFF landscape: convergence in many key technical and regulatory aspects — plus flexibility to adapt to local conditions.

Ultimately, European vs. Asian airport fire trucks is less a strict dichotomy than a spectrum: many “Asian” fleets are built with European designs; many “European” airports use the same operational standards as their counterparts in Asia. Differences often come down to context — not ideology.